Box Installation

Flexible, adaptable and space efficient. For all different parts of the industrial hemp plant we have a solution which best fits its needs using a box installation. Boxes allow for easy filling and internal transport and provide an enclosed micro climate for drying and retting the hemp components.

Compatible with harvesting methods

Efficient internal transport

Maximal use of floor space

Tried and tested installation

Minimal risk of spoilage

Minimal expense of energy

How can we help?

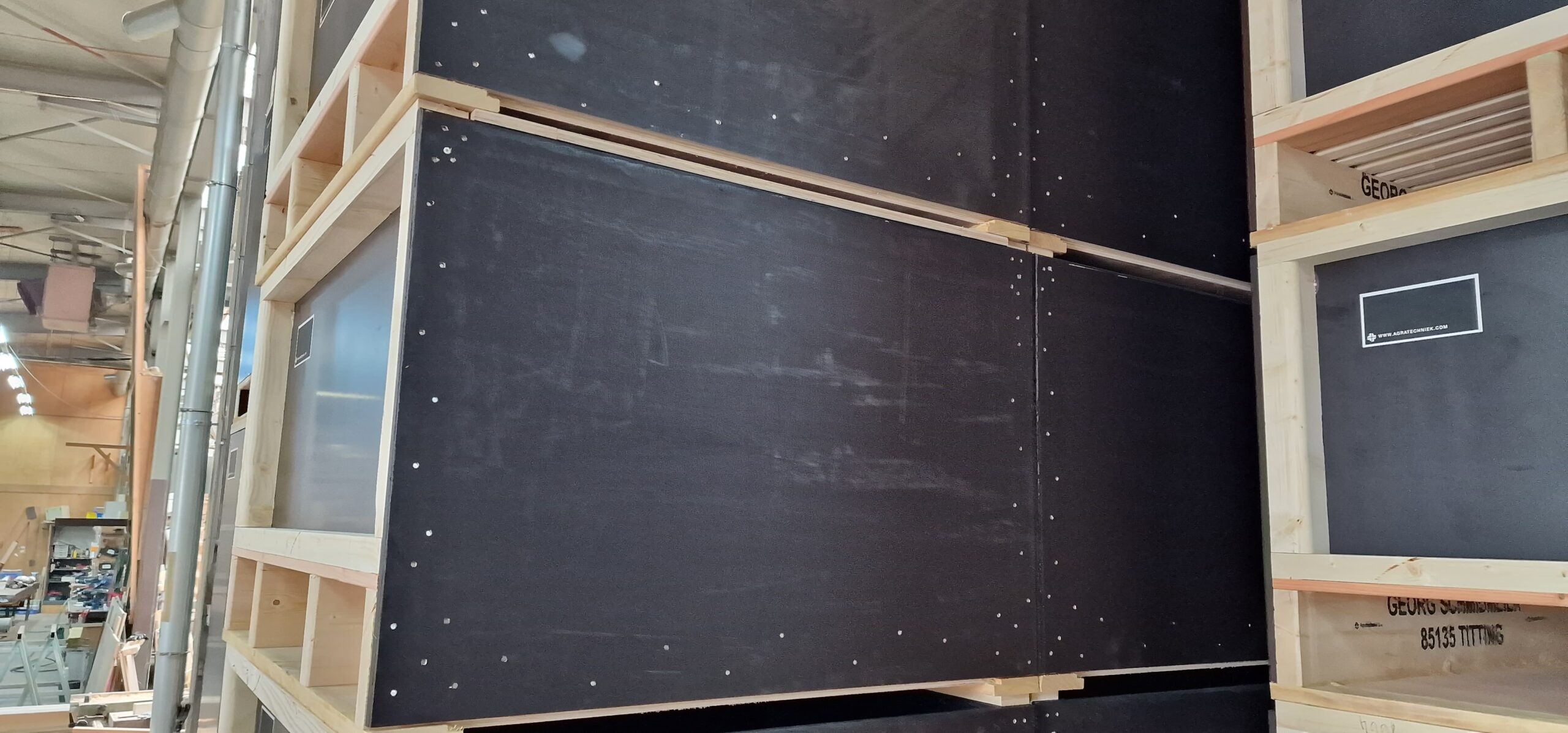

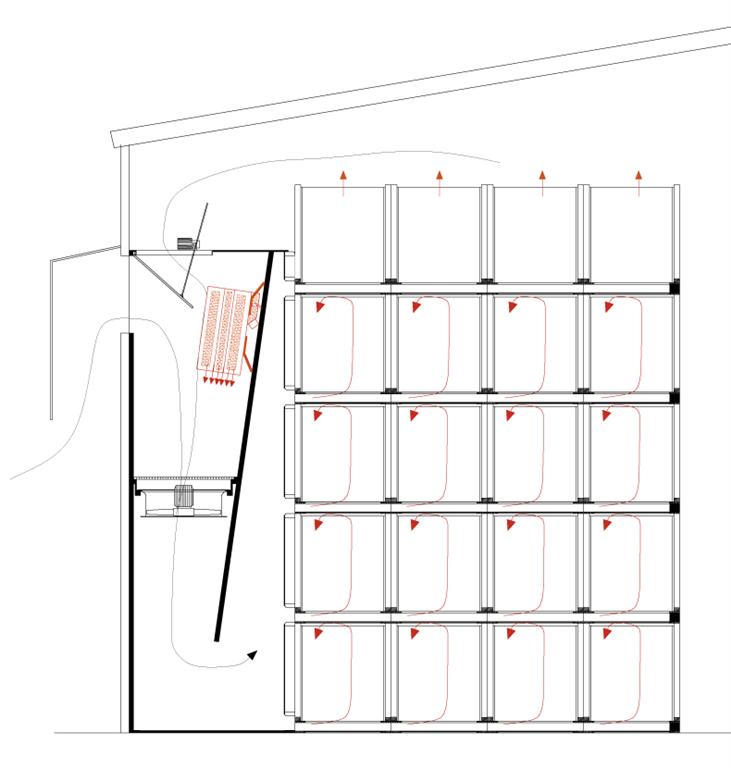

Of our drying solutions, box drying is our most used method for agricultural drying applications. This is done in front of a large scale drying wall allowing for directed airflow per level of boxes and great flexibility and scalability. Volumes up to 105 m3 per row are possible. For the hemp stalk we facilitate the retting process, directed under controlled conditions. Drying of the hemp seed, flower/leaf or stalk will commence in an automatic, gradual and controlled manner. All with complete insight and control with our ABC-software through the measurement of temperature, humidity and airflow.

How do the boxes work together?

Boxes made of special water-resistant plywood give you the maximum drying volume on minimaal floor space. With different heating source options, this highly efficient drying method dries your hemp products precisely, automatically and economically.

Each box is designed to receive optimal airflow, so the product inside is dried or retted optimally. The size of a single box ranges from 1m3 to 3.5m3.

Products

Let's start work together

+316 833 320 78

t.pankras@hemp-drying.com

Kruiswijk 14, 1761 AR

Anna Paulowna, NL

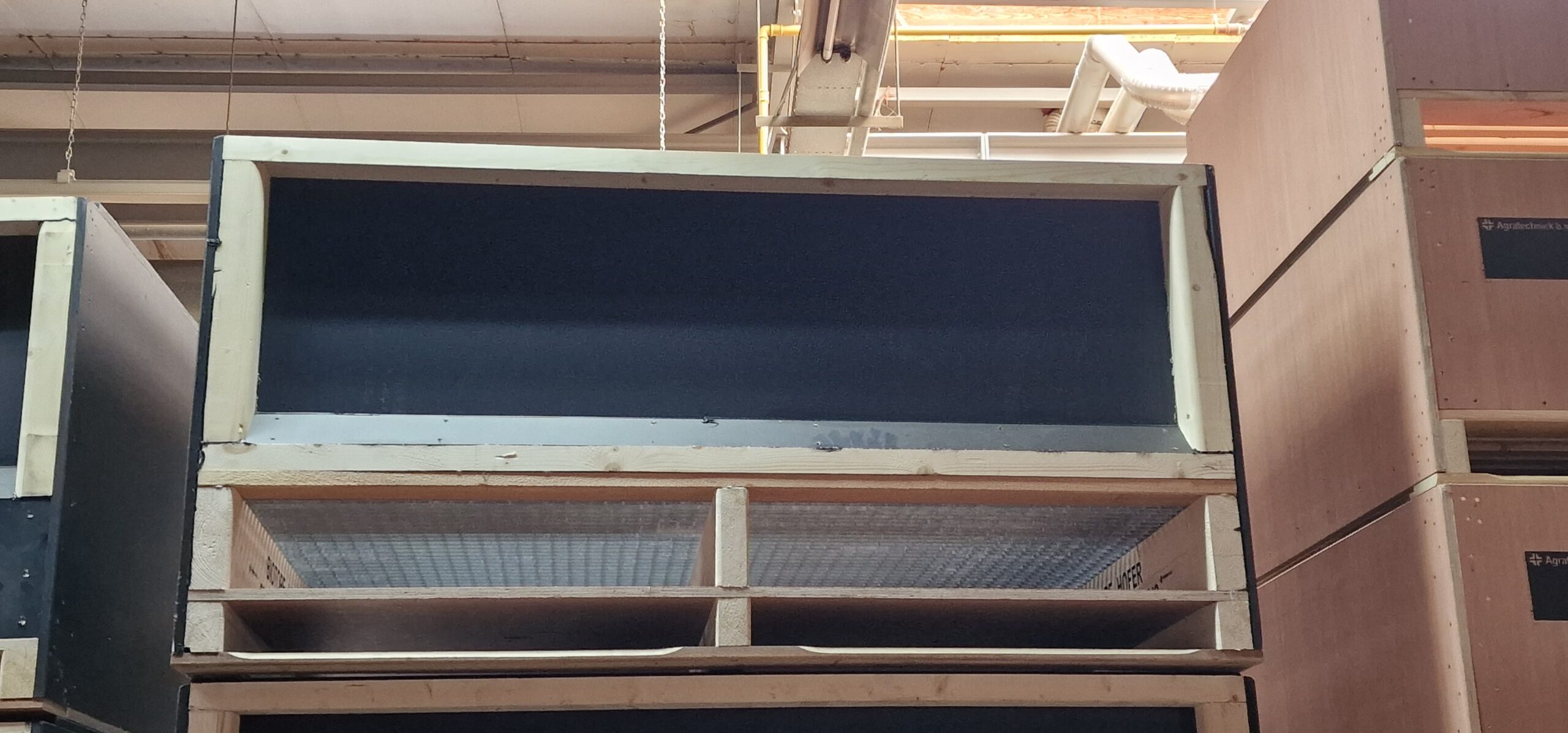

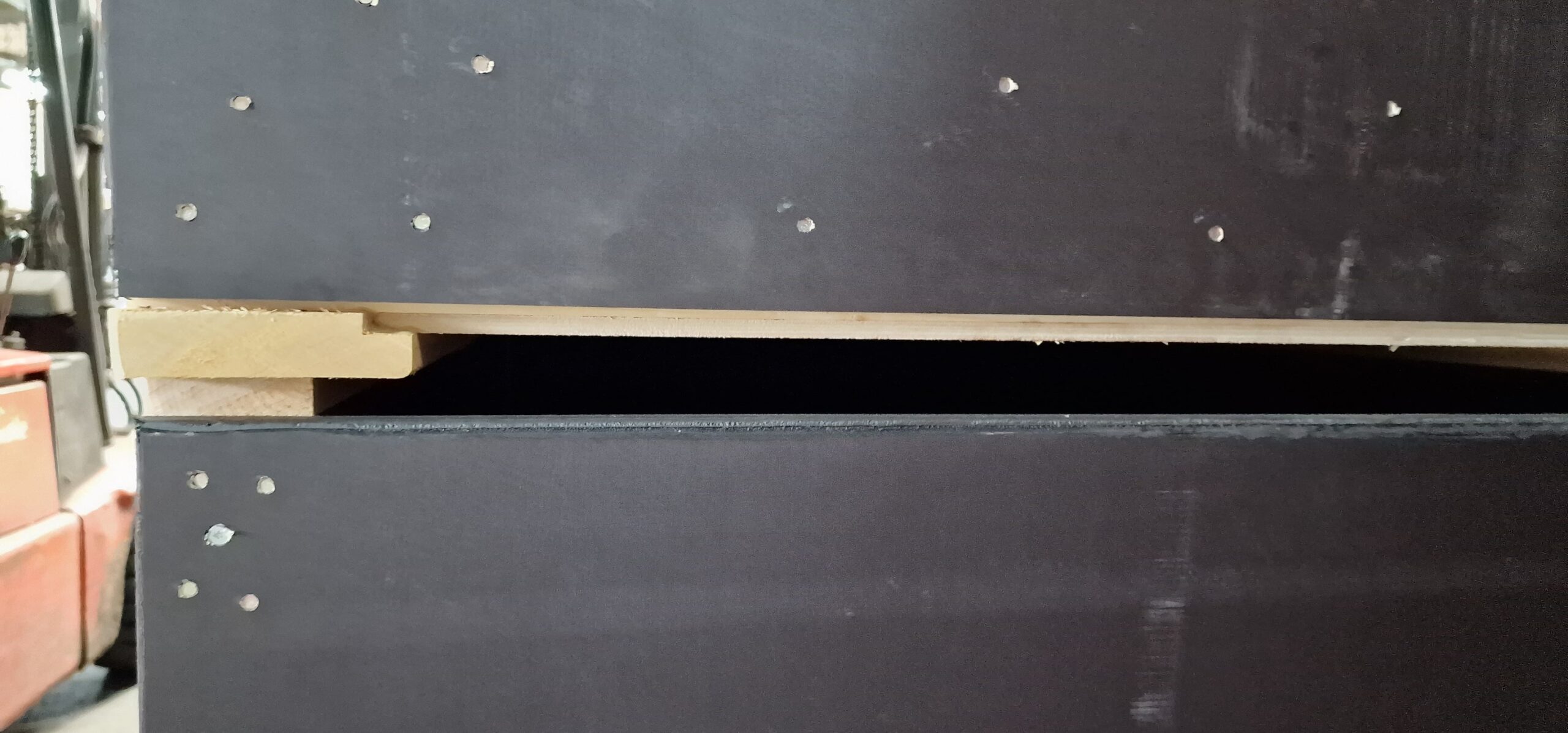

Pallet bottom closed by 9mm plywood

——————————————————

Difference in thickness between plywood and hardwood plank

Difference makes openings between box layers for escaping moist air on

each box layer dfdfjdndfnhdbfdfddf

Boxes are placed in front and on top of each other before an air distribution unit. That contains a heating element and ventilator.

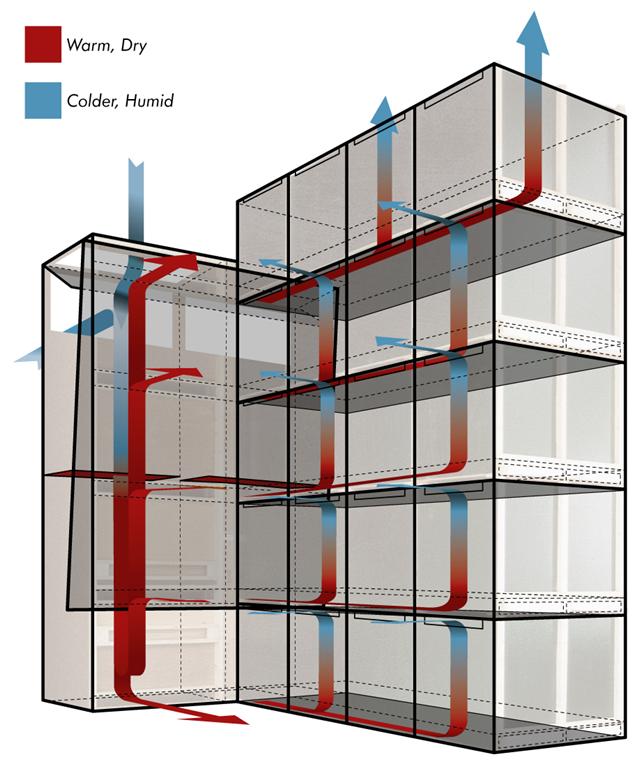

Dry and warm air adsorbs moisture from the product and moist air escapes per layers out of the product.

A fan extracts outdoor or indoor air. Air will be heated and dried and distributed over the box levels.

With extra provision, the pallet can be flipped safely by a forklift

Box cannot move between the pile. The pallet cannot be damaged. This enables a smooth dosing of the product.

Working Process

Our hemp drying process is a seamless journey designed to deliver optimal results for your hemp crop. Here’s a brief overview of the three essential steps:

Consultation

In an open conversation, we discuss your drying or retting need. We will advise you on the best installation for your situation.

Design and Work

From this point we will bring your installation from imagination, to technical design, to reality. The installation will be installed on site and is ready for use.

Complete & Maintenance

We will help you get familiar with your new installation and explain proper use and maintenance.