Solutions

Let's start work together

+316 833 320 78

t.pankras@hemp-drying.com

Kruiswijk 4, 1761 AR

Anna Paulowna, NL

Stalk Retting and Drying

Hemp stalks are strong and rugged. Before processing can start, the ‘glue’ holding the fibers and woody core together needs to break down sufficiently through retting and the product needs to be dried. We do this in a box or container installation, under control of our ABC-software.

We combine the 50 years experience we have gathered working with agricultural products for a retting and drying solution combining the best parts of nature and our knowledge and solutions. During the harvest of hemp stalks they can be placed immediately in an aerated bulk storage installation. All year round the stalks can be deposited in one of our containers or boxes; according to the capacity of the decortication and processing facility.

How does it work?

For the clean and efficient extraction of high quality fibers of consistent quality from hemp (or flax), a controlled and precise retting process of the stalks is needed.

Harvest

- Harvesting the hemp stalks and placing them parallel on the field

- Let the stalks dry on the field

- At a stable moisture content less than 15% the hemp is baled and harvested

- The bales are stored and retted throughout the year

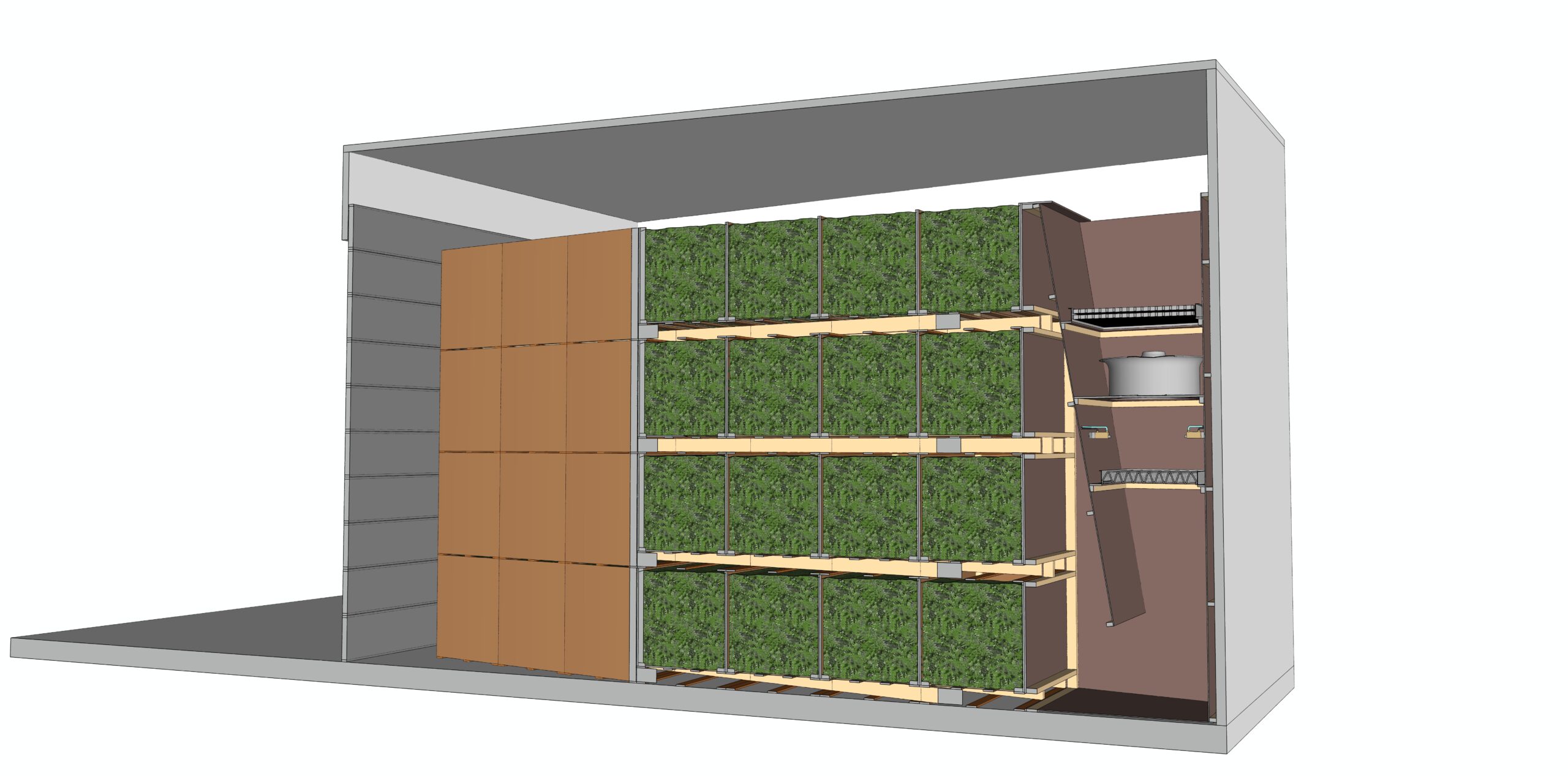

Controlled retting installation

- Bales are opened up and rolled off parallely into Hemp-Drying.com boxes

- Microbes are added while the boxes are filled

- The boxes are placed in front- and. ontop of each other in the controlled retting installation

- Conditoned air is distributed per box layer

- First, the stalks are dried slightly for a more consistent retting outcome

- The right conditions are created for the retting process

- At the desired retting stage, the process is stopped

- The stalks are dried to the desired moisture content for scutching

Processing

- The stalks are retted according to the capacitity of your scutching line

- The stalks are dried to the ideal moisture content for scutching

- The Hemp-Drying boxes are conveyed to the scutching installation

- The boxes are tipped over to feed parallel hemp stalks to be scutched

- The scutching line is turned to the controlled retting outcome quality & supply

- This results in precise and effective separation of the fibers and hemp hurds

Working Process

Our hemp drying process is a seamless journey designed to deliver optimal results for your hemp crop. Here’s a brief overview of the three essential steps:

Consultation

In an open conversation, we discuss your drying or retting need. We will advise you on the best installation for your situation.

Design and Work

From this point we will bring your installation from imagination, to technical design, to reality. The installation will be installed on site and is ready for use.

Complete & Maintenance

We will help you get familiar with your new installation and explain proper use and maintenance.