Solutions

Let's start work together

Kruiswijk 4, 1761 AR

Anna Paulowna, NL

+316 833 320 78

t.pankras@hemp-drying.com

The Drying Theory

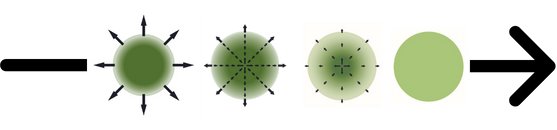

For water molecules to be contained in air they need to be moving. This requires the air to have energy in a form of temperature. This means that the maximum amount of moisture that air can hold is related to the energy present in the air.

The amount of grams of moisture in one kilogram of air is called the Absolute Humidity (AH). The amount of grams of water in the air in relation to the maximum water capacity of the air is expressed in a percentage, called the Relative Humidity (RH) of air.

Substraction of Moisture

When the absolute humidity in the air that gets blown through your product is lower than the absolute humidity in the product, this air will absorb moisture and your product will dry until the surrounding air and the air in the product are in balance.

We make use of this principle by measuring the ingoing and outgoing absolute humidity. This enables us to dry your product controlled to the desired moisture content. The difference between the outgoing and incoming absolute humidity is called Delta Absolute Humidity.

How to Dry Efficiently?

To dry the different parts of the industrial hemp plant to the desired moisture content, we have developed three products based on our knowledge of drying techniques and environmental control.

Working Process

Our hemp drying process is a seamless journey designed to deliver optimal results for your hemp crop. Here’s a brief overview of the three essential steps:

Consultation

In an open conversation, we discuss your drying or retting need. We will advise you on the best installation for your situation.

Design and Work

From this point we will bring your installation from imagination, to technical design, to reality. The installation will be installed on site and is ready for use.

Complete & Maintenance

We will help you get familiar with your new installation and explain proper use and maintenance.